AAC/ALC panel introduction in detail

I think we all are familiar with those big wide long and white panels on the construction site, the workers erect a wall is very easily. Actually it is not only simply but also environmentally-friendly, And that’s the new construction material I want to talk about today –AAC/ALC panel.

|

The construction site of AAC/ALC Panels

|

The construction technology process of AAC/ALC panels

|

AAC/ALC (shorted for autoclaved aerated concrete) panels. The Chinese name is Autoclaved Lightweight Concrete, are mainly made of silica sand, cement, aluminum, lime, gypsum, processing in the condition of high temperature, high pressure and steam curing. They could be used in industry buildings and residential buildings.

Actually no matter ALC/AAC Panel or NALC panels, they all are the shorted for autoclaved aerated lightweight concrete panels, our national product standard is GB15762-2008.Any domestic enterprise must follow the technology standard. Whether the main materials are fly ash , silica sand , industrial tailings or ore sand, the chemical composition all are silicon calcium salt. Just different form of existence in nature.

The profile of AAC/ALC panels

AS the new popular product in the building industry, compare with traditional construction materials, ALC panel have several unique advantages, the materials not only has good heat insulation [λ=0.13(W/m.k)]but also has better thermal insulation,(Storage coefficient S=2.75W(m.k)]. With the reasonable thickness it can be used not only in cold areas where high insulation requirements but also in hot summer and cold winter areas where heat insulation is required, to meet the requirements of energy conservation standards and energy-saving standard.

The AAC/ALC Panel of technical index

Sound insulation:Sound insulation for Autoclaved Aerated Concrete panels of 100mm is 40.8db, while 150mm is 45.6db. There are a lot of separate crystal-shaped blowholes in the panel, so the panel has the features of sound insulation and acoustic absorption.

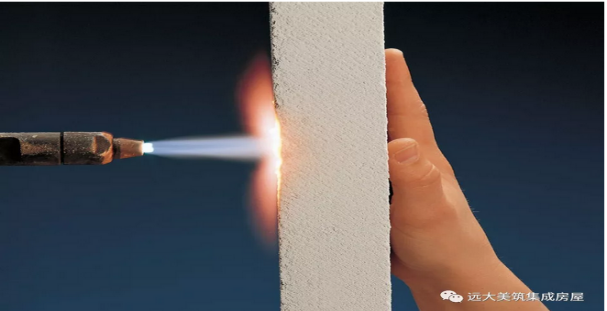

Fireproofing: the fire-resistant time for AAC panels of 100mm is 3.42hours while 120mm is 4 hours. The raw materials of AAC panels are totally inorganic and incombustible, and will not volatilize noxious gas even under the high temperature. The product is especially suited for fire-rated applications.

The fireproof experiment of AAC/ALC panel

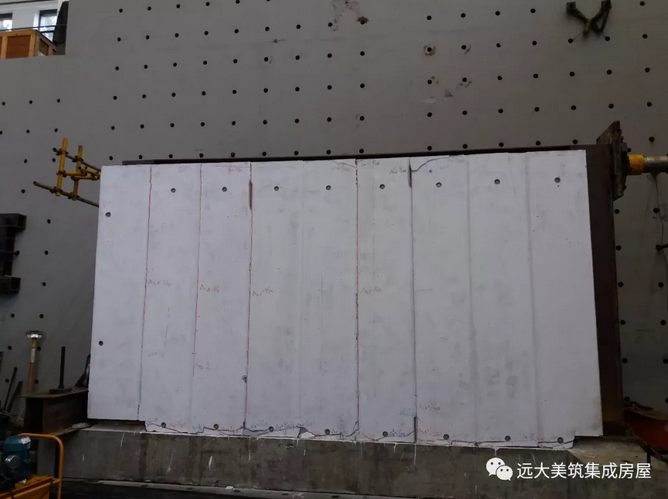

Anti-seismic:As a building envelope, AAC panels are known for their excellent anti-vibration by architects. In a simulated earthquake experiment (seismic intensity 10.5), none of the panels fracture, and joints of test construction are undamaged.

The Anti-seismic experiment of AAC/ALC panle

Freezing resistance: Good freeze-resistance, quality loss after freeze-thaw test <1.5% (national standard <5%), strength loss <5%(national standard <20%)

Durability: AAC panels are building materials of inorganic silicate and not affected by harsh climatic conditions and will not degrade under normal atmospheric conditions. The service life matches with all kinds of construction.

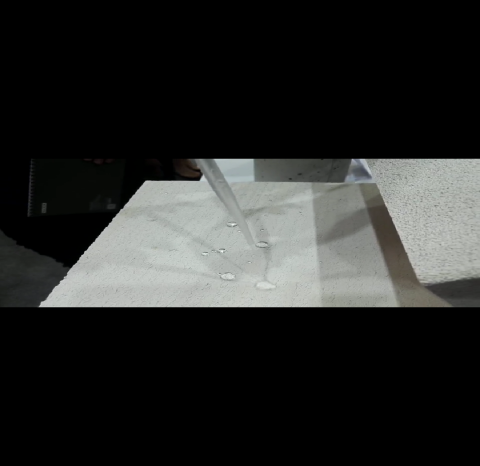

Anti-permeability: good permeability, five times better than standard brick

Construct ability: ALC panel quick and easy installation, because the material can be routed, sanded, or cut to size on site using standard carbon steel power tools

Environmentally friendly:This material is non-radioactive, no harmful gas escape, is a kind of green environmental protection material

Environmental protection: The Autoclaved Aerated Concrete is designed for consumers who are environmentally conscious. It helps reduce at least 30% of environmental waste, decrease over 50% of greenhouse radiation and over 60% integrated energy on the surface of brick.

Suitability: ALC panel has a complete application supporting system, equipped with special connector, sewing agent, repair powder, interface agent, etc

Softening coefficient:the high softening coefficient,Rw/Ro=0.88;

Simple construction and low cost:Adopt the AAC/ALC panel without furring, low cost RMB 20-25/㎡,puttying and coating directly

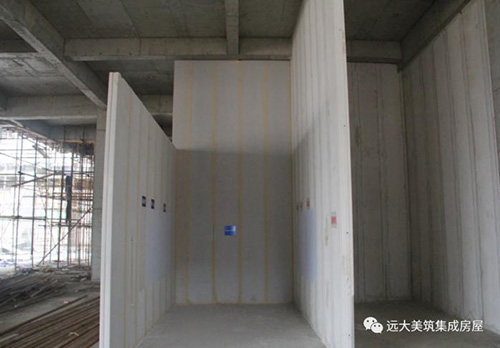

AAC/ALC panels are used in high-rise apartment buildings with steel structure

Good surface quality and non-cracking: because this material is used for dry construction, there is no air drum crack on the plate surface.

The purpose of AAC/ALC Panel

Because of its superior material characteristics, it has been widely used in internal and external wall panels, roof panels, floor panels, and decorative panels. It is a mature building material with superior performance, simple installation and flexibility.

|

AAC/ALC Internal panel

|

AAC/ALC External Panel

|

|

AAC/ALC Floor Panel

|

AAC/ALC roof panel

|

|

AAC/ALC decorative panel

|

AAC/ALC Panel + Coating

|

Shandong Yuanda Innovative Materials Co., Ltd is professional in innovative construction materials of walls. Our company has introduced German production techniques and realized industrialization of construction industry for insulated external walls, AAC panels fabricated walls, etc. We have 8-year professional experience of development and application in the construction field, such as wall materials, steel-structure buildings. We can supply all-around service from fabrication designing to building operations.

The main products are: ALC/AAC (Autoclaved Lightweight/Aerated Concrete) panels, AAC blocks with function of thermal insulation, AAC accurate blocks. Mortar are produced by German m-tec Machinery & production techniques. The factory occupies 180,000 square meters and has 2 production lines. The annual production amounts are: 400,000 cubic meters of panels and 600,000 cubic meters of AAC blocks. Our products sell well not only in China, but also in Australia, New Zealand, Korea, Southeast Asia, Africa, middle east, etc.

If you needed wall materials and request for fabrication of the materials, please feel free to contact us! We will provide the best service! We sincerely welcome customers to visit our factory!

|

The Rizhao factory of Shandong Yuanda Innovative Materials Co., Ltd

|

The corner of production workshop

|

|

Ready for shipping

|

Ready for shipping

|

Projects

|

Korea villa with RCB system two-stories with ALC panel in process

|

Guyana villa with ALC panel

|

Brunei dormitory with ALC panel

Shandong Yuanda Innovative Materials Co., Ltd is professional in innovative construction materials of walls and we are sincerely welcome you to visit our factory

Contact Us:

Shandong Yuanda Innovative Materials Co., Ltd

Address: No. 20 Zhuzhou Road, Laoshan District, Qingdao, Shandong Province, China

Tel: +86 137 9199 4562(Whatsapp/Viber)

+86-532-8099 6919

Website: www.yuandachn.com/en/

shandongyuanda.en.alibaba.com

Email: sales<@>yuandachn.com